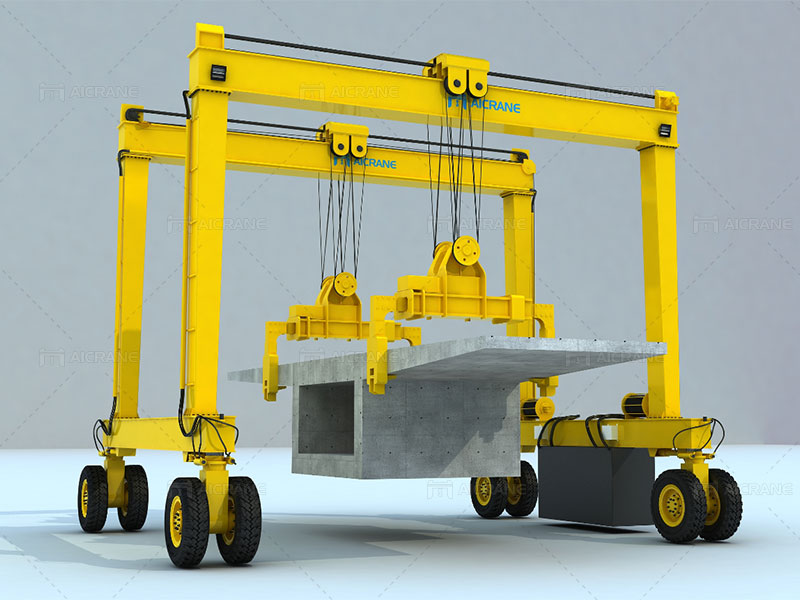

Rubber tyred gantry cranes (RTGs) are essential heavy-duty equipment used in various industries, such as ports, intermodal facilities, and container yards, for efficient container handling and transportation. When considering the purchase of an RTG, one of the primary concerns for buyers is the price. The price of an RTG can vary significantly, and understanding the factors that influence the cost is crucial for making informed decisions. In this article, we will delve into the key factors that affect the rubber tyred gantry crane price and unravel the cost puzzle.

Load Capacity and Size:

The load capacity and size of an RTG are fundamental factors that impact its price. Higher load capacity and larger crane sizes require more robust structures and powerful components, leading to a higher manufacturing cost. When purchasing an RTG, it is essential to match the crane’s load capacity to the specific requirements of the handling tasks it will perform.

Span and Outreach:

The span of an RTG refers to the distance between the two legs of the gantry, while the outreach is the distance the crane can reach horizontally from the gantry legs. A longer span and outreach allow the crane to cover a larger area, making it more versatile and suitable for handling containers across multiple rows. Naturally, a larger span and outreach result in a higher price due to the additional materials and engineering complexity involved.

Hoisting Height and Speed:

The height to which the RTG can hoist containers and the hoisting speed are essential factors influencing the price. RTGs with higher hoisting heights and faster hoisting speeds require more powerful motors, increased structural reinforcement, and precision control systems, which contribute to a higher cost.

Automation and Technology:

Automation and advanced technology can significantly impact the price of an RTG. Fully automated RTGs, equipped with features such as remote control, anti-collision systems, and container identification technology, offer increased efficiency and reduced labor costs. However, the integration of such sophisticated technology can also raise the overall cost of the gantry crane.

Power Source and Energy Efficiency:

The choice of power source for an RTG, such as diesel, electricity, or hybrid systems, can affect the crane’s price. Electric and hybrid RTGs are generally more energy-efficient and environmentally friendly than their diesel counterparts, but their initial cost may be higher due to the incorporation of advanced power systems.

Manufacturer and Brand Reputation:

The reputation and brand recognition of the RTG manufacturer can influence the crane’s price. Well-established and reputable manufacturers may charge a premium for their products due to their track record of delivering high-quality and reliable equipment. However, it is essential to balance brand reputation with the specific needs and budget constraints of the buyer.

Customization and Additional Features:

Customization options and additional features can also impact the RTG’s price. Some manufacturers offer various add-ons and customization choices to tailor the crane to the specific requirements of the buyer. While these options can enhance the crane’s performance, they may also add to the overall cost.

Service and Support:

The level of service and support offered by the crane manufacturer is another factor to consider. Comprehensive after-sales support, including maintenance, spare parts availability, and technical assistance, can add value to the purchase and justify a higher price.

Market Conditions:

Market conditions and economic factors can influence the price of RTGs. Supply and demand dynamics, currency fluctuations, and changes in raw material costs can all impact the final price of the crane.

In conclusion, the price of a rubber tyred gantry crane is influenced by a combination of factors, including load capacity, size, span, outreach, hoisting height, and speed. Additionally, the choice of power source, automation level, brand reputation, customization, and market conditions all play a role in determining the final cost. Buyers must carefully evaluate their specific requirements and budget constraints while considering these factors to make an informed decision and invest in an RTG that meets their operational needs efficiently and cost-effectively.