Investing in a stone crusher plant is a significant financial commitment, but understanding the lifecycle costs can help businesses make informed decisions. From initial setup to long-term maintenance, these expenses will impact your overall return on investment (ROI). In this article, we’ll break down the various factors that contribute to the lifecycle costs of stone crusher plants, helping you get a clearer picture of what to expect.

Initial Investment: Purchase and Setup

Cost of Equipment

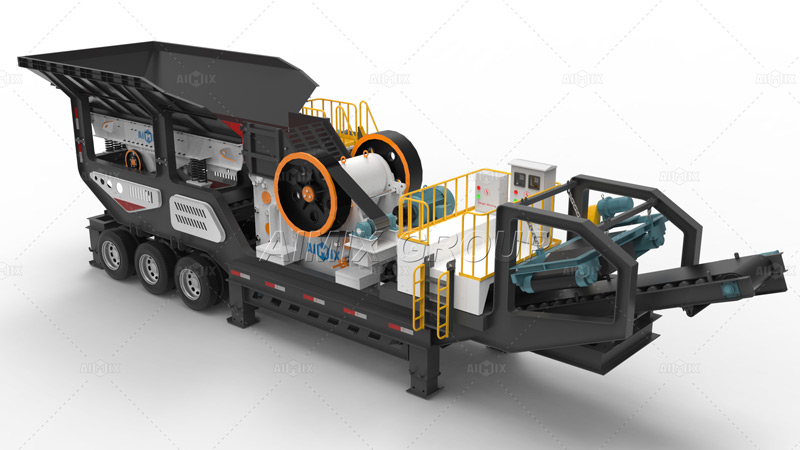

The first major cost when investing in a stone crusher plant(planta chancadora de piedra en Perú) is the purchase of the equipment. This includes crushers, conveyors, feeders, and screening units. Different types of stone crusher plants come with varied price tags, depending on their capacity and features. For example, a mobile stone crusher plant may cost more due to its portability but offer flexibility in moving between job sites.

Installation and Site Preparation

After purchasing the equipment, you’ll need to prepare the site where the stone crusher plant will be installed. This often involves grading the land, creating access roads, and setting up the necessary utilities like power and water. The size and complexity of the installation will directly influence these costs.

Mobile Stone Crusher Plants vs. Stationary

There is an important choice to be made between mobile stone crusher plants and stationary ones. Mobile plants typically have a higher upfront cost but offer more flexibility in terms of location. Stationary plants, on the other hand, require a fixed installation site, which may lower transportation costs in the long run but restrict mobility.

Operating Costs: Fuel, Energy, and Labor

Fuel and Power Consumption

One of the most significant ongoing expenses for a stone crusher plant is fuel or energy consumption. Mobile stone crusher plants are powered by diesel or electric engines, while stationary plants often rely on electric power. The type of fuel used and the plant’s overall efficiency will directly impact your energy costs. Over the lifespan of the plant, this can be one of the most significant contributors to operating expenses.

Labor Costs

Operating a stone crusher plant requires skilled labor. From equipment operators to maintenance technicians, these costs will accumulate over time. For mobile stone crusher plants(Para plantas trituradoras móviles), there is often an added expense of hiring operators skilled in managing mobile units, while stationary plants usually have more predictable staffing needs.

Raw Material and Wear Parts

Stone crusher plants are built to handle tough materials, but the raw material processed can cause wear and tear on the machinery. Regularly replacing wear parts like jaws, hammers, and screens is necessary to keep the plant running efficiently. Additionally, the cost of raw materials like stone and gravel used in the crushing process also adds to the operational expenses.

Maintenance and Repair Costs

Routine Maintenance

To keep a stone crusher plant running efficiently, routine maintenance is a must. This includes everything from checking the alignment of conveyors to replacing worn-out parts. Mobile stone crusher plants often require more frequent maintenance due to the strain of being transported and set up repeatedly.

Unexpected Breakdowns

In addition to routine maintenance, unexpected breakdowns can occur, leading to downtime and expensive repairs. Regular inspections can help identify potential issues before they turn into costly problems, but it’s crucial to budget for unexpected maintenance events as part of the plant’s lifecycle costs.

Transportation and Logistics Costs

Moving Equipment to and from Job Sites

For mobile stone crusher plants, transportation is another significant cost factor. Moving equipment between job sites can be time-consuming and expensive, especially if the site is remote or difficult to access. On the other hand, stationary plants may have lower transportation costs but incur higher expenses if the stone needs to be transported to different locations.

Raw Material Transportation

In addition to moving the equipment itself, transporting raw materials to and from the stone crusher plant(planta trituradora) also adds to the overall lifecycle costs. Efficient logistics planning can help minimize these expenses, but the distance between the quarry, job site, and plant can have a substantial impact on costs.

Long-Term Considerations: Depreciation and Resale Value

Depreciation of Equipment

Over time, the equipment used in stone crusher plants will depreciate in value. This is an important factor to consider when calculating lifecycle costs. While well-maintained equipment can last for decades, the value of the plant will decrease as it ages. Understanding the expected depreciation rate can help you plan for equipment replacement or upgrades in the future.

Resale Value

At the end of a stone crusher plant’s useful life, selling or scrapping the equipment can offset some of the initial investment. Mobile stone crusher plants often retain more value due to their portability and versatility, making them a better long-term investment in some cases. However, resale values will also depend on market demand and the condition of the equipment at the time of sale.

Environmental and Regulatory Costs

Environmental Impact and Mitigation

Operating a stone crusher plant, particularly a mobile stone crusher plant, can have significant environmental impacts, including dust, noise, and vibrations. Mitigation measures such as dust suppression systems and noise barriers can add to the cost of running the plant, but they are often required to meet regulatory standards.

Permits and Compliance

In addition to environmental costs, permits and compliance with local regulations also factor into the lifecycle costs of a stone crusher plant. Depending on the location and the scope of the operation, securing the necessary permits can be both time-consuming and costly. Ensuring compliance with environmental and safety regulations is essential to avoid fines and legal issues. And if you need to buy a stone crusher plant, I recommend you a reliable manufacturer: https://aimixgrupo.com/

Conclusion

Understanding the lifecycle costs of a stone crusher plant is crucial for making an informed investment decision. From the initial purchase and installation to ongoing maintenance and eventual resale, every phase of the plant’s lifecycle comes with its own set of expenses. Whether opting for a mobile stone crusher plant or a stationary one, carefully weighing these costs against the plant’s potential profitability will help you maximize your return on investment. Proper planning and regular maintenance can further help to reduce overall costs and ensure the plant runs efficiently for years to come.